Customized microstructures: the key to new ceramics

Aluminum oxide matrix: The proven foundation

Modern high-performance oxide ceramics are predominantly based on mixed ceramics with an aluminum oxide or zirconium dioxide matrix. In aluminum oxide matrix materials, strength and fracture toughness are increased by the targeted addition of zirconium dioxide. The properties of zirconium dioxide can be influenced as a metastable component by adding yttrium and/or cerium oxide.

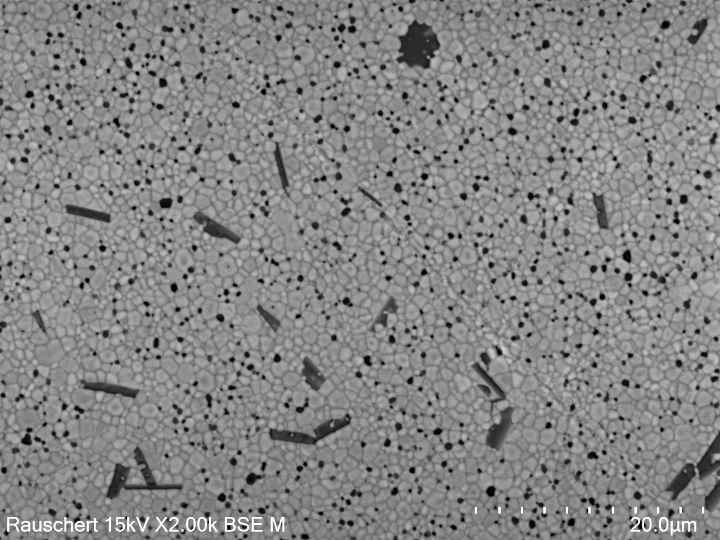

Another proven reinforcement mechanism is the incorporation of hexagonal platelets. Appropriate process control during sintering triggers solid-state chemical reactions that ultimately result in tailor-made microstructures. These controlled reactions make it possible to precisely tailor the microstructure to the desired properties.

More complex systems for higher performance with zirconium dioxide matrix

Similar mechanisms play a decisive role in zirconium dioxide matrix materials. However, in this case, the matrix must first be stabilized by adding appropriate oxides. By adding aluminum oxide and other platelet-forming oxides, such as strontium oxide or lanthanum oxide, the microstructures of the individual materials can be specifically influenced by suitable process control.

One particularly interesting feature is the possibility of creating a special microstructure with bimodal characteristics by incorporating hexagonal platelets and globular grains. This dual structure combines the advantages of both grain shapes and results in an optimized balance between strength and toughness.

Customized properties through controlled process management

Customized materials with impressive mechanical properties can be produced through chemical composition and appropriate process control. The achievable strengths are up to 1500 MPa, while fracture toughnesses of up to 15 MPa√m can be realized. These values significantly exceed those of many conventional materials.

A key advantage of these new generations of ceramics lies in their hydrothermal resistance. Unlike Y-TZP ceramics (yttrium-stabilized tetragonal zirconium dioxide ceramics), these materials exhibit significantly improved long-term stability in moist environments, which greatly expands their range of applications.

The future of high-performance ceramics

The development of these tailor-made ceramics demonstrates the enormous potential of modern materials technology. By precisely controlling the microstructure on different length scales, properties can be achieved that far exceed what was possible with conventional ceramics.

Our materials experts are continuously working on the further development of these innovative materials in order to constantly optimize their performance.

This opens up new fields of application in high-temperature technology, medical technology, and other demanding areas where mechanical strength, fracture toughness, and long-term stability are required.

Do you have a specific application in mind for high-performance ceramics?

With over 125 years of experience in technical ceramics, we work with our customers to develop customized solutions for demanding industrial applications. From material selection and process optimization to series production, talk to our ceramics experts about your project.