Solid electrolyte innovation: Rauschert drives sodium battery technology forward

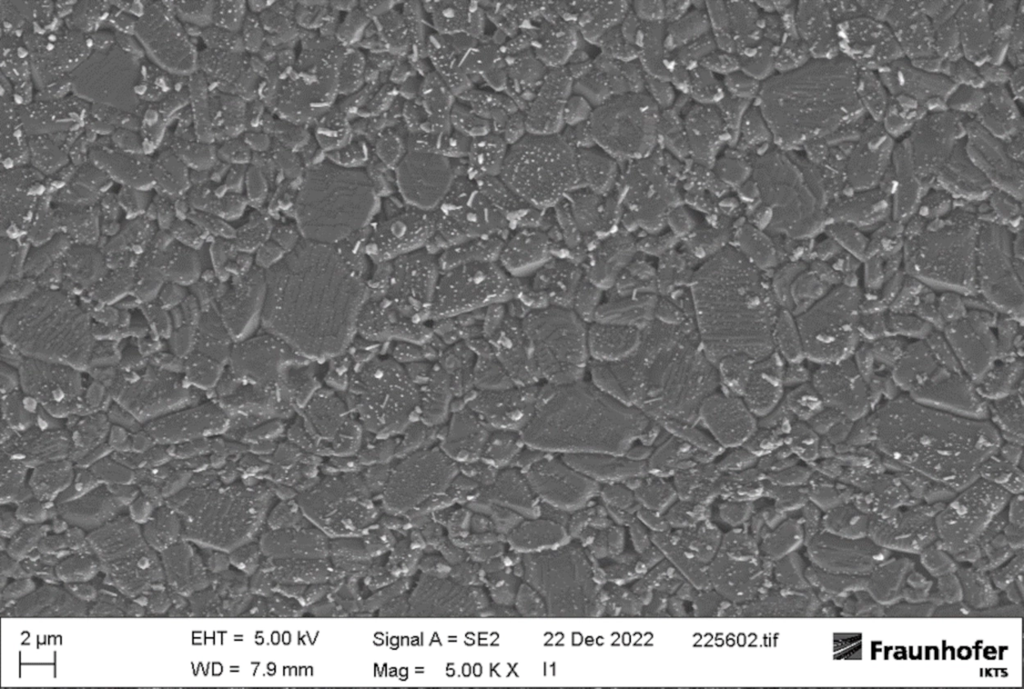

[Translate to English:] Gefüge des entwickelten ꞵ-Aluminiumoxids

As part of the successful KeNaB-ART research project (funding code: 03XP0404B), Rauschert has made an important contribution to the development and industrial production of ceramic solid electrolytes for sodium-ion batteries. Under the project leadership of Dr. Rolf Wagner, an innovative process for the production of ꞵ-alumina electrolytes was established, which forms the basis for a new generation of safe and resource-efficient energy storage solutions.

Technological innovation for sustainable energy storage

Sodium-ion batteries (SIB) are considered a promising alternative to conventional lithium-ion batteries, especially for stationary applications such as home storage or microgrids in climatically challenging regions. The cell concept developed in the KeNaB-ART project consists of a liquid metal anode, a ceramic solid electrolyte, and a sodium-ion cathode. This technology is characterized by its high temperature stability, safety, and resource conservation, as it requires neither cobalt nor lithium.

Rauschert´s contribution: Key component solid electrolyte

As a specialist in technical ceramics, Rauschert took on the task of developing ceramic solid electrolytes based on ꞵ aluminum oxide. This involved both basic material development and conversion to an industrial spray process. In addition, a special process for dry pressing the developed compounds was established.

Successful industrialization

One particular success of the project lies in the scalability of production. The electrolyte powder made from ꞵ aluminum oxide was successfully produced in industrial plants with the required quality. The production of electrolytes using dry pressing was also successfully implemented. Rauschert is now able to produce and supply ꞵ aluminum oxide on an industrial scale—an important prerequisite for the future commercialization of sodium solid electrolyte batteries.

Significance for energy storage systems

The technology developed is particularly suitable for stationary energy storage systems with an operating temperature of over 100 °C. By dispensing with active cooling even in systems above 500 kWh, there is considerable potential for cost-efficient and sustainable energy storage solutions.

The collaboration within the project consortium with IBU-tec advanced materials AG, Fraunhofer IKTS, and EL-CELL GmbH has created a solid foundation for further developing sodium solid-state batteries in terms of storage capacity, cycle stability, and charging and discharging rates, thereby increasing the technological maturity of the technology.