Optimal solutions for metal foundries

Our high-performance ceramic materials enable long service life, high temperature resistance and optimum performance in melting applications for various casting processes. With our high level of ceramic expertise and innovative strength, we develop tailor-made solutions for new requirements in casting technology.

Your advantages – Maximum process reliability

- High temperature resistance up to 1,100°C

- Very low wetting of molten aluminium

- High strength up to 300 N/mm2

- High density up to 3 MPa

- Long service life up to 2 years

- Good corrosion resistance

- Chemical resistance

- Low thermal expansion

- Selection of optimal materials for various areas of application

Our high-performance ceramics impress with their high temperature resistance, low wetting of non-ferrous melts and excellent strength. They are corrosion and chemical resistant, extremely durable and ensure reliable processes.

Our experts are always available to provide you with further advice.

Silicon nitride

- Riser tubes

- Thermocouple protection tubes

- Dosing tubes

- Heating tubes

- Impeller

- Stopper plates

- Customised parts

Aluminium oxide

Products for the foundry industry

With our reliable products, we increase the efficiency of your processes.

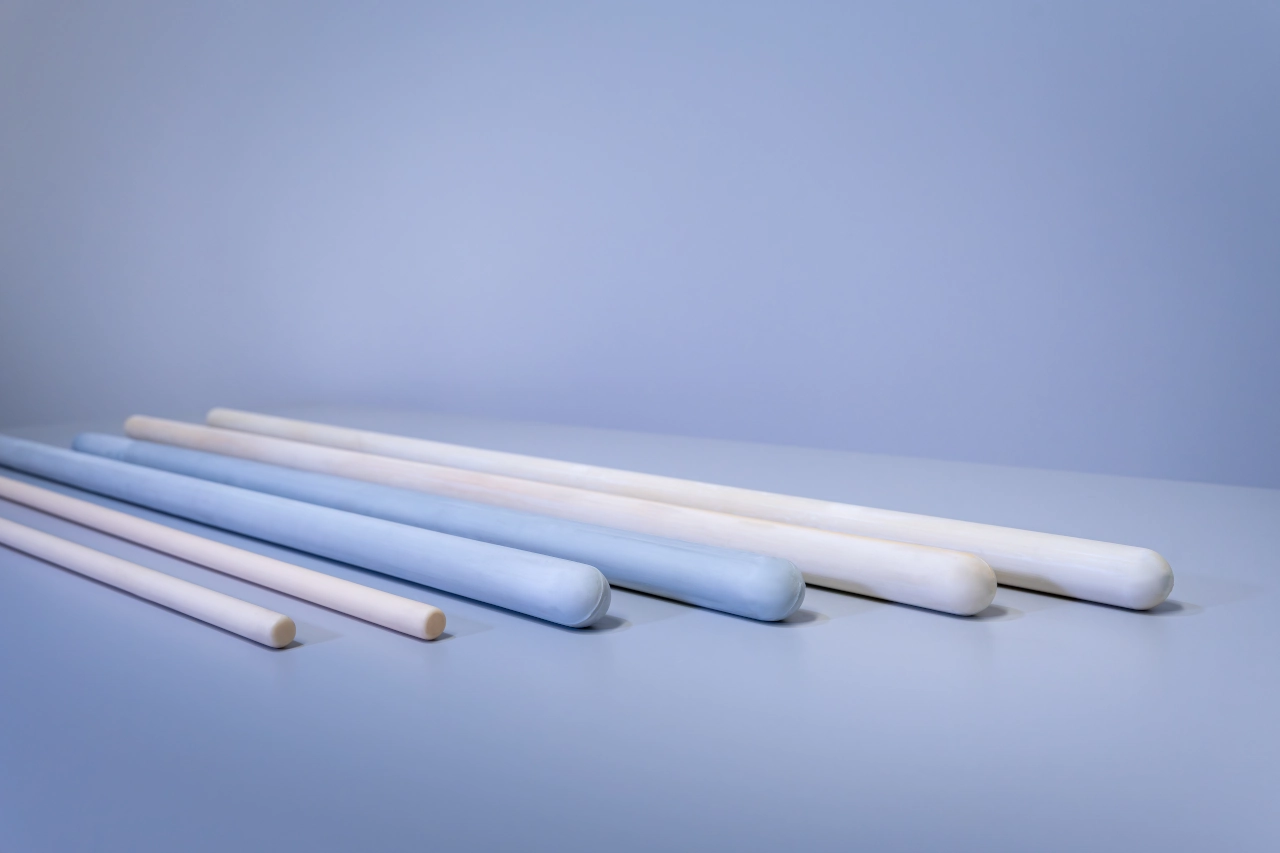

Riser/dosing tubes

Durability through the highest material quality

Our riser and dosing tubes made of aluminium titanate (Al₂TiO₅) and silicon nitride (Si₃N₄) offer the highest quality and reliability for use in non-ferrous metal smelting production. Their excellent temperature resistance ensures a long service life and consistent performance during operation. Aluminium titanate in particular impresses with its microporosity, low thermal expansion and non-wettability with aluminium. This makes our tubes ideal for use in aluminium foundries, especially in low-pressure die casting (LPDC).

In addition to standard sizes, we also manufacture customised components exactly to your design specifications in order to achieve optimum results in your production process.

Thermocouple protection tubes

High-performance tubes for non-ferrous melting

Our ALTITE® thermal protection tubes and silicon nitride and NSN protection tubes are specially designed for use with non-ferrous metals. These materials are characterised by their excellent thermal shock resistance and are ideal for aluminium casting due to their low wettability. Thermal conductivity ensures quick temperature measurement and protection for the thermocouple, while the very low thermal expansion coefficient minimises stresses in the material. This combination of properties means that our products offer maximum reliability and optimum process reliability in demanding casting operations.

Casting cores

Dimensional stability down to the last detail

Our all-ceramic casting cores for the HPDC-LC process impress with their maximum dimensional accuracy, dimensional stability and temperature resistance. They enable the production of even the most complex internal contours and guarantee clean, precise workpieces without residues. Via UHP water cleaning, the cores can be removed without leaving any residues, ensuring efficient further processing. With our ceramic casting cores, you can rely on innovative technology, maximum quality and reliability in every casting process.

Bushings/Nozzles/Break rings

Durability meets precision

Our bushings, nozzles, insulating rings and break rings made of aluminium titanate (ALTITE®) are specially designed for long service life and precise casting processes. Thanks to their high thermal shock resistance and low wettability, they ensure clean, stable metal flow and integrate perfectly into your production process. The components are used in numerous casting processes – from high-pressure to low-pressure casting – and impress with their outstanding material properties: high thermal insulation (<1 W/mK), very high thermal shock resistance, low wettability with non-ferrous metal melts, an extremely low thermal expansion coefficient of 0.05 1/K *10-6 and peak temperature resistance up to 1300 °C.

Heating tubes

Reliable heat transfer at maximum performance

Our silicon nitride (Si₃N₄) heating tubes offer impressive mechanical strength, excellent thermal conductivity and non-wettability with molten aluminium. This ensures even heat distribution and reliable performance even under the most demanding conditions. Standard sizes are available. Special designs can be manufactured individually according to your requirements.

In addition to classic heating tubes, we also offer components made of aluminium titanate (Al₂TiO₅) and silicon nitride (Si₃N₄) in a wide variety of shapes – from plates and funnels to complex, three-dimensional geometries – for maximum flexibility in your production process.

Customised solutions for your applications

Do you have a suitable application for our materials or assemblies?

Rauschert manufactures customised consumable components and tool parts – as special designs or contract production – exactly according to your requirements.

With our extensive, innovative material portfolio and a modern, global production network, we offer you maximum flexibility and precision.

Talk to us – our technology solves your challenge.

- Silicon nitride Si3N4

- Porous silicon nitride (NSN)

- Corderite C520