Complete solutions for wire drawing and cable manufacturing processes

High-performance ceramics significantly increase the service life and efficiency in demanding mechanical engineering applications. Special surface qualities extend machine runtimes and reduce maintenance costs, sustainably optimizing your processes. With our refurbishment service, you receive customized complete solutions from a single source.

Optimally adapted tools for your requirements

The tools used must be precisely tailored to the requirements of the drawing process in order to preventpermanent damage to the wire surface. The tool surfaces require large contact areas and optimal roughness. By precisely controlling the particle sizes of the ceramic materials used, we ensure excellent surface quality and roughness of the tools.

With our advanced manufacturing methods, we guarantee thermal and hydrothermal stability under demanding operating conditions.

Our customers benefit from tribological excellence through:

- Longer machine service life & reduced costs

- Increased process reliability & fewer downtimes

- Maximum wear resistance

- Extended tool life

- Tailor-made solutions for their specific requirements

Rauschert is continuously advancing in this field through its TechCenters.

Products for wire drawing and cable manufacturing processes

With our reliably high-quality products, you can optimize your processes and avoid unplanned downtime caused by machine wear or failure.

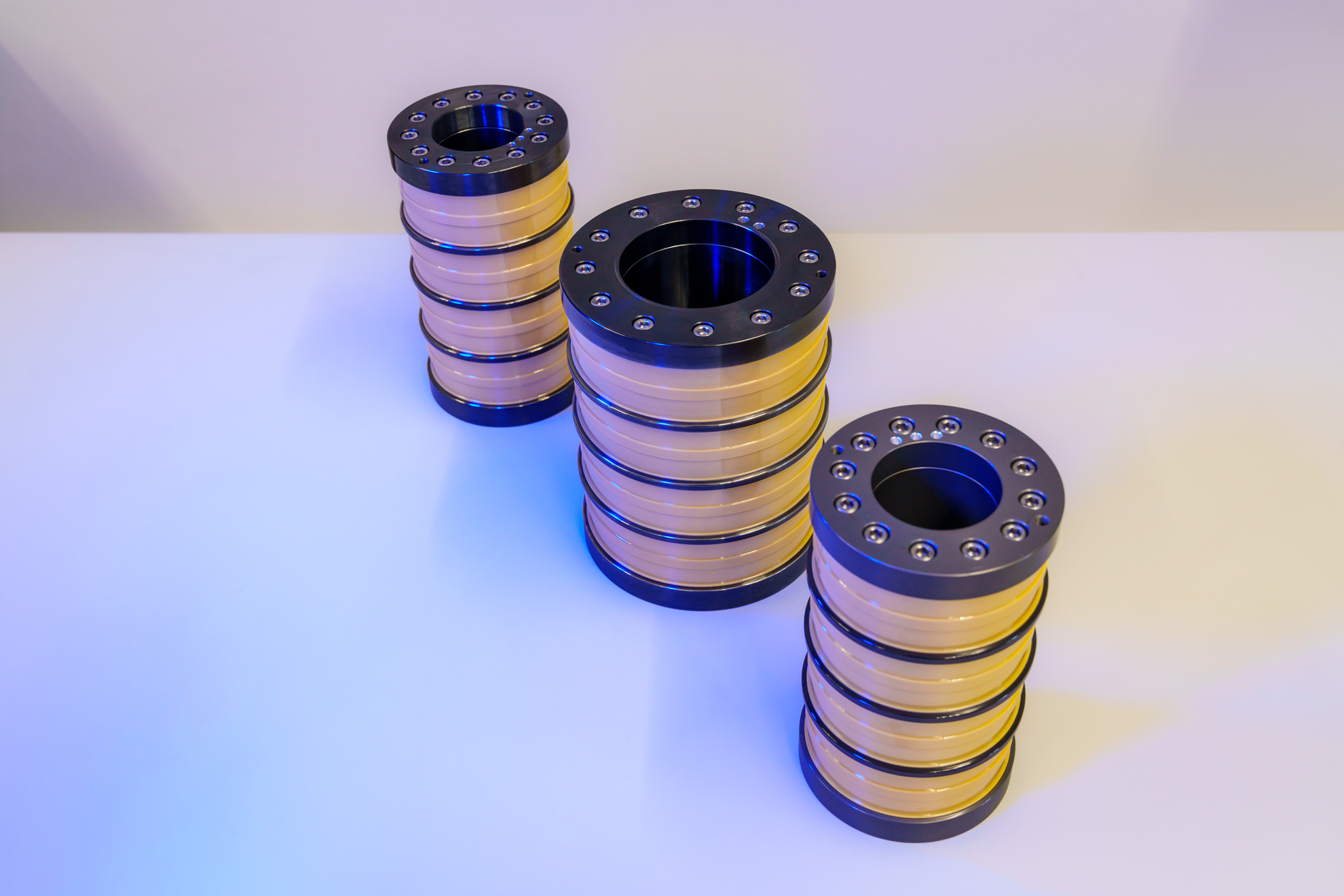

Drawing roller

for process-safe wire drawing in multi-wire machines

Our drawing rollers made of MgO-stabilized zirconia or high-purity alumina are characterized by excellent wear and temperature resistance. The optimized surface structure ensures defined sliding friction and minimizes wire breaks in the continuous drawing process.

Standard dimensions: Diameter from 50 mm to 135 mm, 2-step to 16-step designs

Materials: MgO-stabilized zirconia, yellow or white

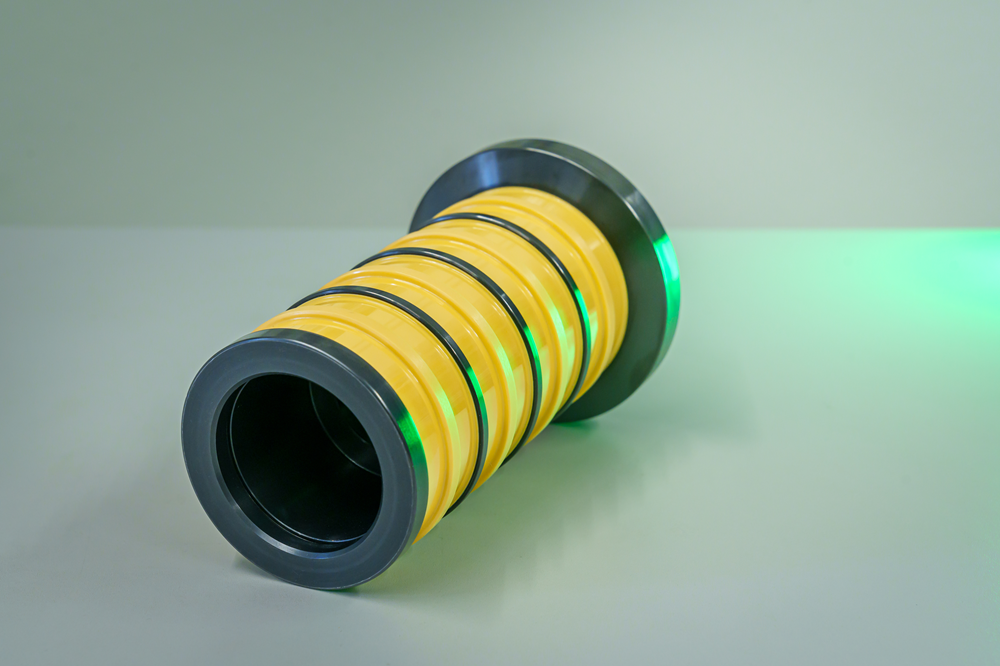

Drawing cones

for stable processes in fine wire drawing

Our drawing cones made of wear-resistant zirconia or alumina ensure consistent wire guidance and stable friction conditions, even at high drawing speeds and with the smallest wire diameters. The ceramic materials offer excellent fracture toughness and enable long service life with minimal maintenance requirements.

Drawing cones can be designed as full ceramic or composite constructions.

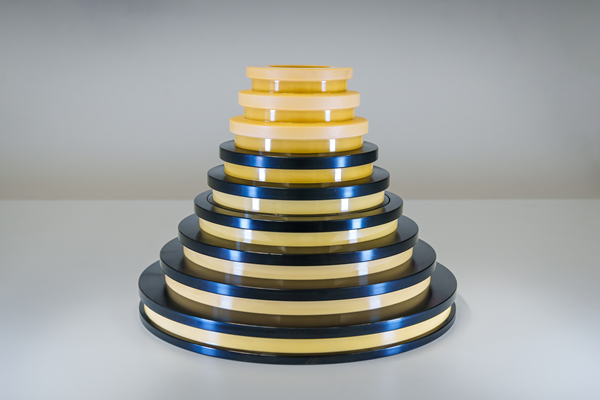

Drawing rings and eyelets

for precise wire guidance

Our highly wear-resistant drawing rings for coarse wire drawing are available in diameters up to 500 mm.

The eyelets and wire guide elements ensure precise wire guidance, reliably preventing surface damage and wire contamination.

Thanks to finely tuned geometries and smooth, tribologically optimized surfaces, they are ideally suited for use in high-speed processes and with extremely fine wires.

Refurbishment service

for ceramic surfaces

In wire and cable drawing processes, tool surfaces are exposed to extreme stresses, which can lead to wear over time.

Our experts can refurbish ceramic surfaces according to your specific requirements, allowing tools to be reliably re-integrated into your processes.

Material selection

Zirconia – MgO-stabilized

Our zirconia materials are stabilized with magnesium and are characterized by:

- High fracture toughness

- High strength

Due to their similar coefficient of thermal expansion, zirconia components are particularly suitable for use in combination with steel parts. We offer zirconia in the standard colors white and yellow.

Alumina with purity levels up to 99,9 %

(Rapal® 100/200/1000)

Alumina is a very hard high-performance ceramic material that remains stable at high temperatures and in aggressive chemical environments.

Depending on purity level and grain size, we use it for a wide range of demanding technical applications.

We offer alumina in purity grades from 90% to 99.9%.

For drawing extremely fine wires (some customers process down to 0.003 mm), the ring must be made of alumina.

Further information on Rapal® is available here:

Downloads

Catalogs