Functional ceramics: Why material alone does not define performance

In real applications, performance is rarely defined by the material alone. What truly determines functionality is the interaction between microstructure, geometry and manufacturing process. This interaction governs whether a ceramic component performs reliably, reproducibly and over its intended lifetime.

This system-level view is particularly critical for ceramics with electrical, thermal or chemical functions, where stability and long-term performance are essential.

Function is defined by controlled microstructure

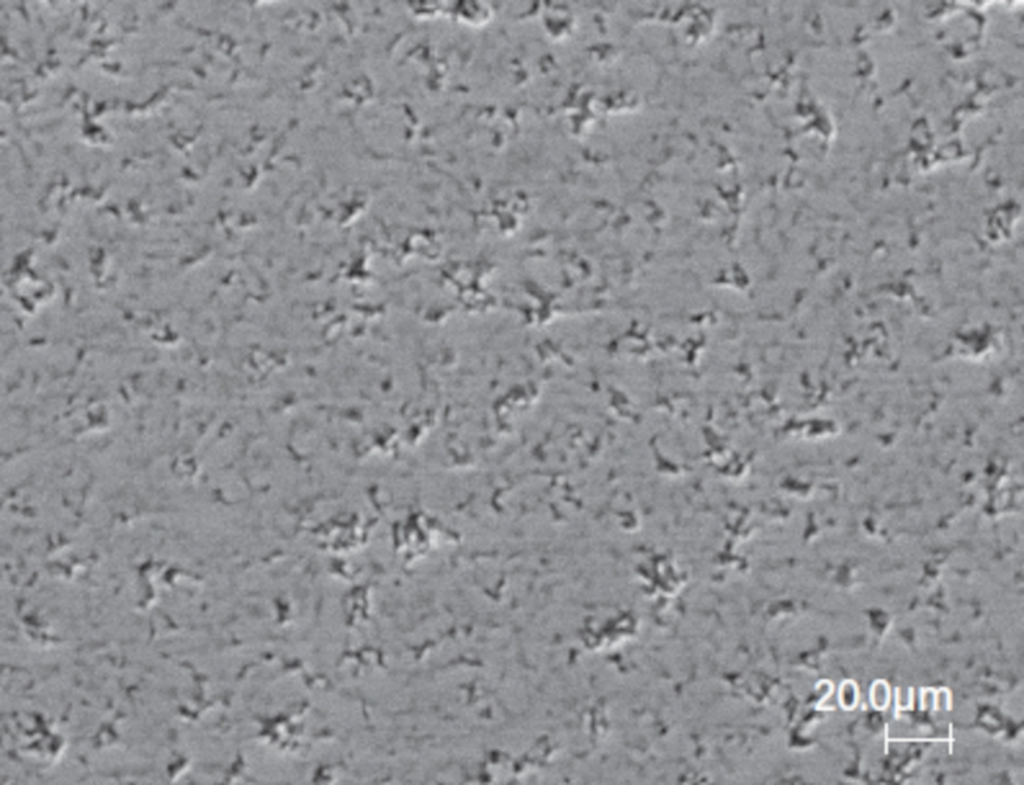

Whether used as an insulation component, diffusion barrier or protective element, the functional behavior of ceramic components is strongly influenced by their microstructure.

Key parameters include:

- porosity and pore morphology,

- pore size distribution and interconnectivity,

- wall thickness and structural homogeneity.

These characteristics directly affect transport phenomena, thermal behavior and mechanical stability. They do not emerge by chance, but are the result of deliberate process decisions, from raw material preparation and forming to debinding and sintering.

When specifications are not function-driven

In industrial practice, problems arise such as:

- variation in component performance,

- property drift over lifetime,

- or premature failures

These are often not caused by the base material itself, but by insufficiently defined or controlled manufacturing and microstructural parameters.

Typical root causes include:

- overly broad tolerances for porosity or density,

- unsuitable sintering windows,

- insufficient alignment between component geometry and functional requirements,

- missing correlation between measured material data and real component performance.

With clearly defined functional objectives, ceramics can help solve problems that arise.

Functional ceramics require CTQ thinking

Successful applications are built on clearly defined Critical-to-Quality (CTQ) parameters, tailored to the specific function of the component. Depending on the application, these typically include:

Microstructure & transport

- open porosity,

- permeability,

- pore size distribution.

Geometry & integrity

- wall thickness,

- dimensional accuracy,

- mechanical stability.

Process & series production

- reproducibility,

- process stability,

- consistency across production batches.

The objective is not to maximize individual properties, but to achieve a balanced optimum for the intended application.

From material selection to system solution

Functional ceramics are not standard components.

Their performance must be understood in the context of the overall system.

Projects are most successful when the interaction between material, manufacturing process and application environment is considered at an early stage. This approach reduces development risk, improves component performance and creates a solid foundation for stable series production.

Planning a functional application or reviewing existing specifications?

Our application engineers support you in translating functional requirements into robust microstructure, geometry and process parameters, enabling reliable performance and stable production.

Let’s discuss your application.