Maximum performance in extreme environments

With our high-performance ceramics, you can rely on maximum energy efficiency, durability, and wear resistance in pump technology. Whether aggressive media, extreme temperature fluctuations, or demanding environments—our solutions stand for chemical resistance and reliable performance in various industries.

Your advantages - Pump components made of Rapal®

- Excellent corrosion resistance

- High temperature resistance up to 1,800°C

- Good wear resistance

- High pressure resistance up to 3,500 MPa

- High hardness up to HV1 2,000

- Lower density between 3.0 and 6.0 g/cm³

- Non-magnetic

- Best surface quality Ra 0.03µ

- Optimal joining technology (metal/ceramic composite)

Wide range of materials for a variety of applications. Thanks to their robustness and resistance to wear, corrosion, and high temperatures, ceramic components from Rauschert have a long service life, which reduces maintenance costs and downtime.

Our experts are always available to provide you with further advice.

Products for the pump industry

With our reliable, high-quality products, you can improve your systems and avoid costly downtime and repairs.

Ceramic Containment Shells

To optimize your magnetically coupled pump

Our Zirconia M containment shells for magnetically coupled pumps optimally transfer the power of the magnetic coupling without eddy current losses and do not transfer any temperatures to the product. Our material is non-magnetizable and electrically non-conductive, thus preventing power losses. Safe use is also guaranteed at high temperatures. The component remains dimensionally stable at high temperatures (approx. 450°C) or high pressures (up to 90 bar). Further details can be found in our flyer.

Piston/Plunger

Ceramic plungers take pumps to a new level

Our ceramics offer high surface quality, which results in optimal sliding properties, thus protecting your seals. Our products are also wear-resistant, which increases the service life of your equipment. Our pistons and plungers can be used for pressures up to 10,000 bar. When used at 3,000 bar, operating times of more than 2,000 hours have been achieved. Compared to carbide, the weight of our ceramics is approximately ⅓. This means that less mass has to be accelerated and decelerated in the pump, which protects its drive.

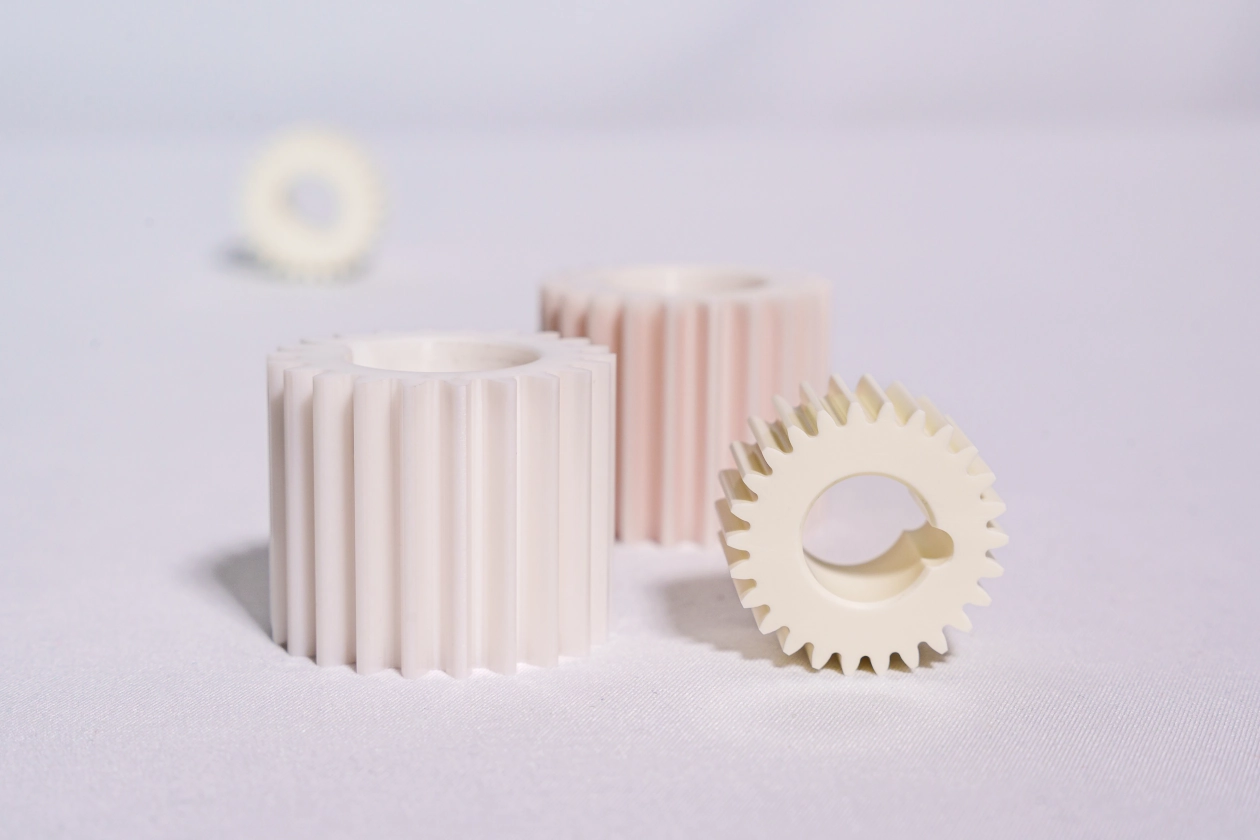

Ceramic gear

High-precision gears for extreme loads

Ceramic gears are ground with maximum precision and significantly increase the service life of gear pumps. Pressures of 300-400 bar are easily achieved with ceramic. Due to their high hardness, ceramic gears do not deform under the most difficult operating conditions; they remain dimensionally stable. Corrosive media do not attack our materials. The tooth geometries do not change over long periods of time and there is no play between the tooth flanks. Minimal leaks remain constant over the entire service life.

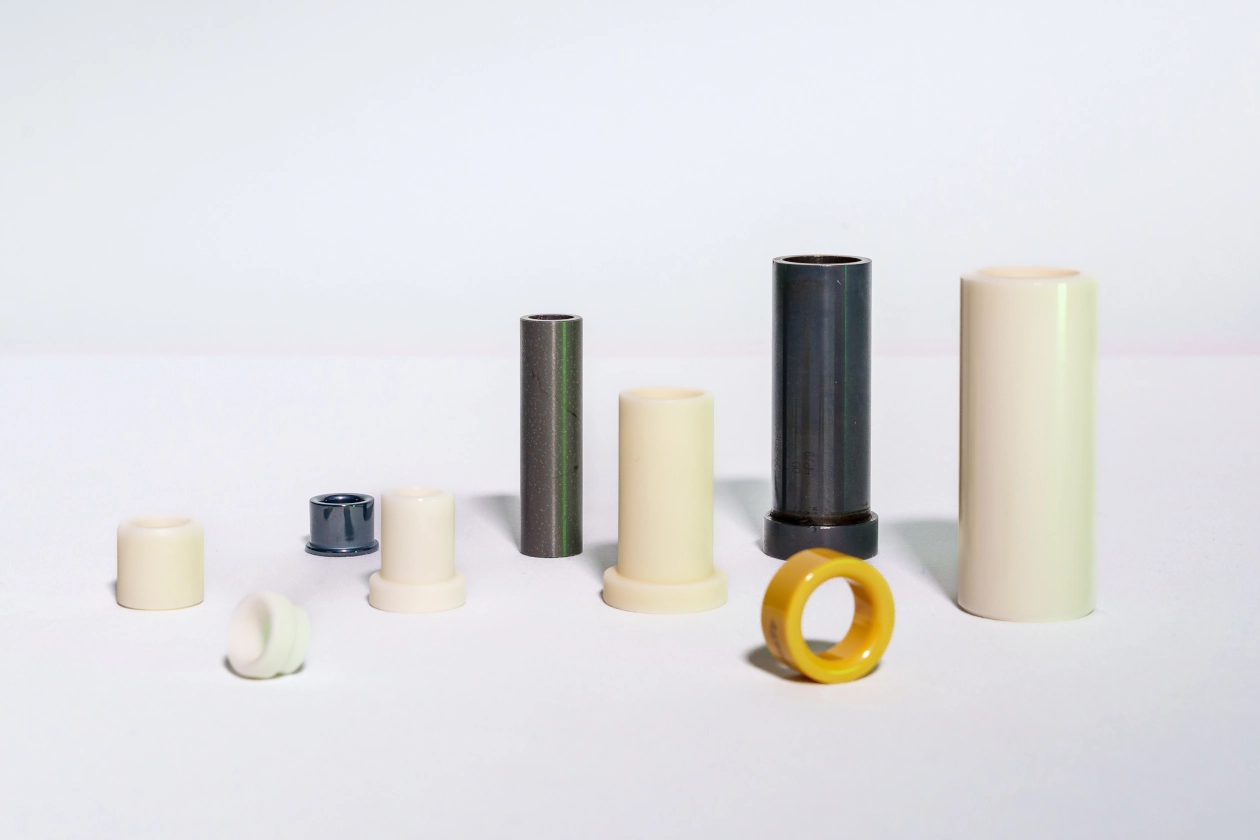

Ceramic plain bearing

Tribologically superior and robust

Our ceramic plain bearings offer outstanding tribological properties and ensure exceptionally high wear resistance in pump applications. With their extreme corrosion resistance and virtually wear-free operation, our ceramic plain bearings stand for maximum service life. Our products demonstrate maximum reliability and performance, even under the highest (approx. 1,800°C) and lowest (-276°C) temperatures, enormous bearing loads (up to 3,500 MPa), and other demanding conditions.

Shaft/Washer

Biocompatible, precise and stable

Our shafts and thrust washers score points for their smooth running and precise dimensional accuracy (<0.001 mm). They usually operate with medium lubrication and retain their robustness and dimensional stability (<0.005 mm) under high loads. Thanks to their excellent running properties at high speeds (40k rpm), low thermal expansion (CTE 1 to 12 10^-6/K), and resistance to corrosion and adhesion, they ensure long-lasting, trouble-free performance in demanding applications. Our ceramics make an important contribution to the medical, pharmaceutical, and food industries thanks to their biocompatibility.

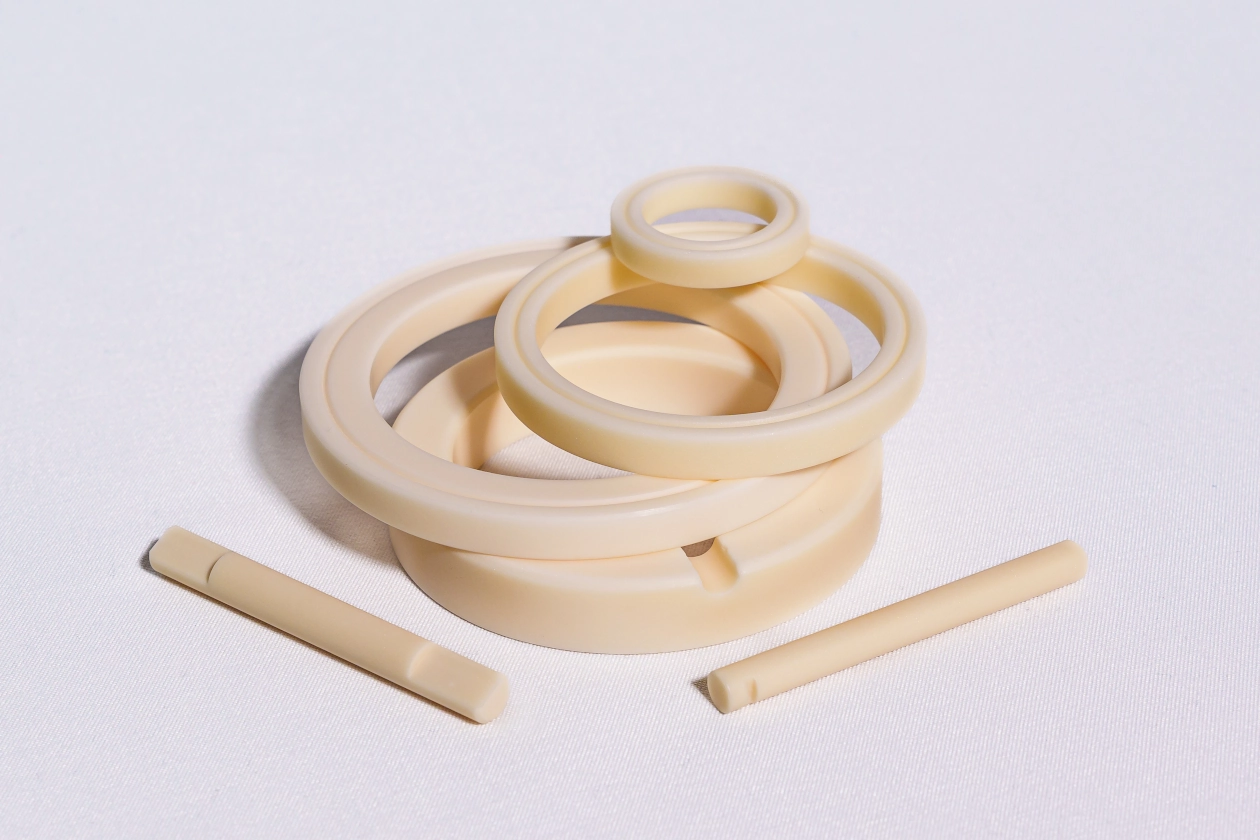

Ceramic valves

Tightness for extreme conditions

Our ceramic valves are characterized by maximum tightness (1*10^-6 mbar*l/s) and complete leak-free operation even at high pressures (up to 1,200 bar) and under demanding operating conditions. They offer excellent wear resistance, outstanding chemical resistance, high temperature stability (approx. 1,500°C), and resistance to abrasive media and cavitation. Thanks to their exceptional impact strength at high frequencies, which occur when the valve is opened and closed, ceramic valves achieve an exceptionally long service life and ensure reliable operation even under extreme operating conditions.

Materialselection

Further information on the materials can be found here.