Maximum output through ceramic solutions in the textile industry

Rauschert develops and manufactures a new generation of ceramic high-performance components. Thanks to superior material properties and innovative surface technologies, they enable longer service life, reduced maintenance costs, and significantly higher production speeds in the textile industry. Our proven solutions ensure a sustainable optimization of your textile processes.

Your advantages in DTY processes

- Excellent yarn properties

- Outstanding efficiency even at high machine speeds

- Long service life thanks to high-quality, chemical-resistant full ceramics

- Easier threading and faster start-up compared to other manufacturers

- Optimized T2/T1 values for stable processes

- “Stay-clean” surface prevents polymer deposits – ideal for solution-spin-dyed yarns

- Full flexibility across all denier ranges and filament counts, from microfilaments to coarse denier yarns

- Uniform dyeability of DTY

These properties make our DTY ceramic components a first-class solution for the highest efficiency, maximum reliability, and consistently superior yarn quality in all areas of production.

Our experts are always available for further consultation.

Products for DTY processes

With our reliably high-quality products, you can optimize your processes, improve yarn quality, and increase machine efficiency at high production speeds.

Rapaltex® Friction Discs

Excellent grip and minimal formation of snow

The Rapaltex® ceramic friction and guide discs deliver superior DTY yarn quality with significantly improved tensile strength and elongation compared to conventional ceramic and PU alternatives. These advanced ceramic discs enable higher machine speeds while maintaining excellent yarn properties, resulting in increased productivity and cost savings.

The innovative “Stay-Clean” surface technology prevents polymer deposits and virtually eliminates the formation of snow, ensuring consistent performance and reduced maintenance downtime. With their exceptional durability and chemical resistance, Rapaltex® discs provide years of trouble-free operation, making them the optimal choice for maximizing DTY process efficiency.

Technical data can be found in our datasheet.

Thread Guides

Precise thread guidance for highest quality

Rauschert high-performance ceramic thread guides ensure excellent yarn properties and uniform dyeability thanks to precisely defined surfaces throughout the entire DTY production chain. These high-quality ceramic components offer significantly longer service life and improved performance, especially with moderately abrasive solution-dyed yarns, which are becoming increasingly important in automotive applications. Strategically positioned between delivery rollers W1 and W2, the thread guides optimize productivity, maintenance intervals, and DTY quality through low coefficients of variation.

Technical data and dimensions can be found in our detailed datasheet.

Twist Stopper

The perfect way to stop twist during texturing

Our twist stopper impresses with its robust metal–ceramic construction and ensures zero defects while allowing easy assembly and disassembly. The high-precision ball bearings and diamond-polished surface made of high-purity alumina ceramic guarantee thread-friendly operation and extended lifetime. Thanks to minimal variation in rotational speed from position to position and easy cleaning, the system provides optimal uniformity for both fine and coarse yarns.

Technical data and part numbers can be found in our detailed datasheet.

Products for POY and FDY processes

Applicators

Precise oil application for maximum efficiency

Rauschert applicators optimize oil uptake through thread-friendly contact geometry, preventing filament damage and yarn breakage. Manufactured from high-purity alumina ceramic, these precision components reduce production downtime due to their low-friction surface. They are ideally suited for microfilament yarns, as well as a wide denier range from below 100 to 3,000 den. With uniform oil application and reduced dripping behavior, yarn quality is significantly improved and spin finish consumption is optimized.

Technical data, denier ranges, and part numbers can be found in our detailed datasheet.

Comprehensive textile ceramics portfolio

for maximum production efficiency

As a leading technology partner, Rauschert offers a complete range of high-performance ceramic solutions for the modern textile industry. From precision spindle components to specialized thread guides, all the way to innovative filtration and coating technologies – our products are perfectly matched and optimize your entire production chain.

Discover our complete product portfolio, designed to support you with state-of-the-art technologies for maximum efficiency and quality!

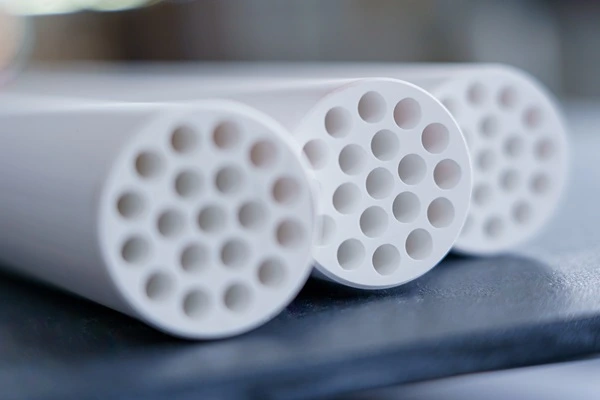

Inopor® Filtration Membranes

Chemical-resistant filtration for cost savings

The inopor® chemical-resistant membranes from Rauschert are used for the filtration of textile wastewater. Applications include, among others, the recovery of caustic soda (sodium hydroxide) during the mercerization of cotton. The technology is also applied in dyeing preparation in the scouring and desizing process. Here, the process water is purified at high temperatures of up to 95°C and returned to the process, which leads to significant energy savings while simultaneously improving the CO2 balance.

If you are interested in this efficient and product-gentle technology, please feel free to contact our qualified inopor®-team at any time.

Innovative Coating Technology

Extended Service Life Through Coating

Rauschert's innovative coating technologies significantly boost the performance and extend the service life of your textile components. These specially developed surface coatings optimize wear resistance, reduce friction, and improve functionality even at the highest operating speeds. By using state-of-the-art coating processes, we achieve significantly longer service intervals and better process stability.